What Is The Process For Resurfacing?

Choice Resurfacing Does Resurfacing Different and Does It Right

- Upon arrival, your technician will thoroughly review the fixture assessing any repairs that might be needed. This is also the time for you and the technician to go over any concerns or questions you have about the process and work schedule.(Note: Please be available either in person on the job site or by cell phone in case questions arise during the process)

- The surface is thoroughly cleaned using industrial strength cleaners.

- Any repairs that are needed are done. Keep in mind that some repairs needed are not discovered until the technician actually gets into the process of doing the actual work. This can be true even if a previous on-site estimate was given. These additional repairs could result in a slightly higher charge for the final work than originally estimated. Our technician should discuss these issues and potential charges as soon as they are discovered.

- Surrounding areas are masked or protected to prevent over spray or damage. Please remove all loose items, rugs, curtains, etc. from the spray area. There is always some dust, etc. that may soil or damage some of these items no matter how careful the technician is. In addition, we have to use adhesive tapes to mask with. These tapes could pull sections of paint or wallpaper along the edge of the fixture being resurfaced.

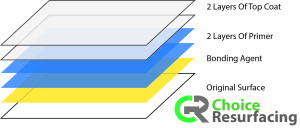

- A powerful adhesor is applied in the form of a chemical bonding agent. Some refinishers either rely on sanding the surface or the use of acids for etching the surface. The stronger the adhesor or adhesion mechanism, the longer the resurfaced finish will last. This part of the refinishing process is key to a successful job.

- After the surface has been properly bonded, the technician will either apply a primer coating and then the final top coat. In some cases, the final top coat is applied directly to the adhesor. Not all surfaces require a primer coating.

- After several coats of the final top coat, your technician may or may not be done with your particular job. Some fixtures require a follow up the next day.

- On this second day your technician will slightly sand out the majority of the dust particles that have settled into the finish and then buff and polish the surface. Most refinishers skip this step all together and don’t take any steps to mitigate the particles trapped in the upper layer of the finish. This is another example of these other refinishers going for the quick money rather than a quality product. Countertop resurfacing normally involves a slightly different process that second day including the application of a high solids clear coat to seal and protect your new counter surface.

- Once the second day detail work is done your technician should complete any caulking, removal of masking materials and debris. There may be some dust that remains when we are done.

- Our technician will explain how to care for your new surface, collect payment, and answer any questions you may have.